1.The sheet-assembled cement silo is designed for resolving the difficulties in export packing on-site silo making construction site transferring extra-high and extra-wide transportation.

2. The sheet-assembled cement silo is a kind of closed storage tank which is safe reliable and convenient to be installed.

3. It has the materials level meter which can display the location and quantity of the materials. And the safety valve on the top of cement silo is used to balance the pressure difference between inside and outside.

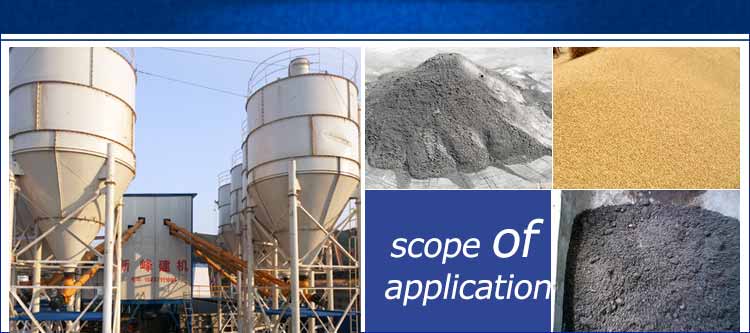

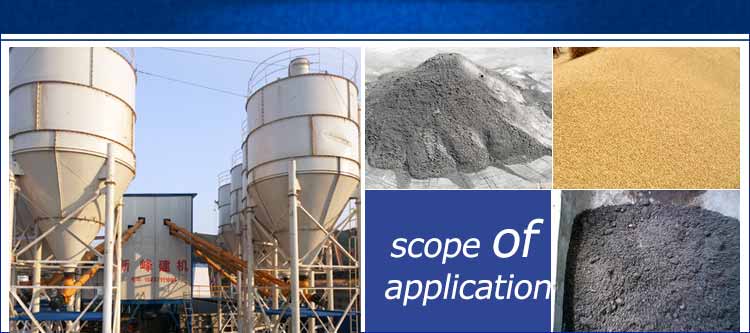

The sheet-assembled cement silo applies to engineering construction concrete mixing stations roads and bridges water conservancy urban construction and other projects. It is also suitable for storing grain cement fly ash and other bulk materials.

1.Waterproof moistureproof prevent the loss of cement reduce urban air pollution small footprint long service life and low cost. It is the environmental friendly construction machinery promoted widely in China.

2. We have a lot of stock of bulk cement silo in general Capacity :100t150t 200t 300t. It can be produced in different size according to user’s requirements.

3. The cement silo is generally cylindrical structure. There are a dust removal equipment on it to prevent dust leakage and a brake device under it to prevent dust caking so the powder can be discharged smoothly.

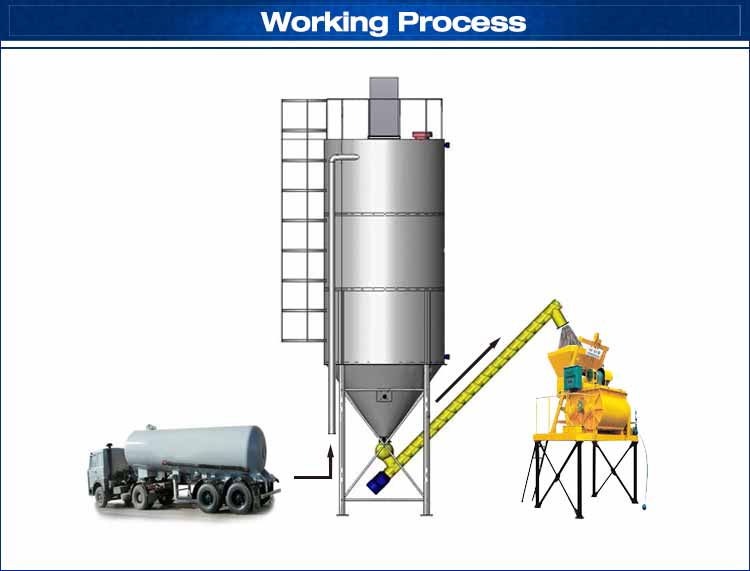

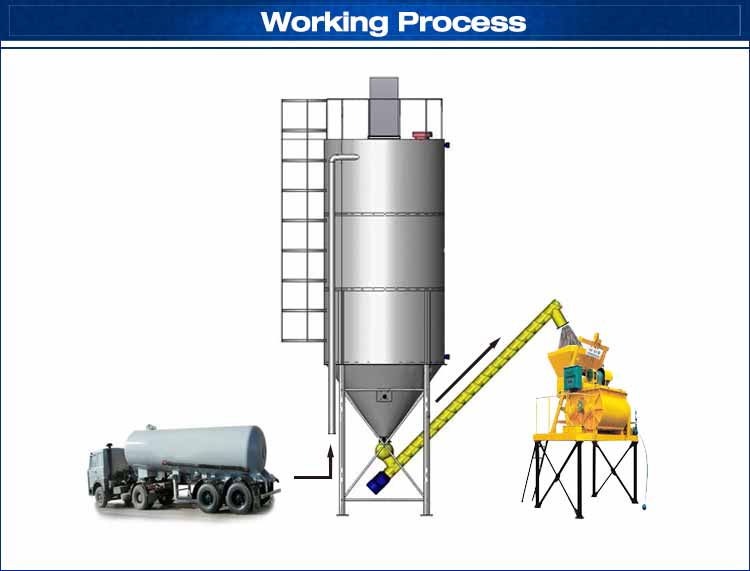

1. Bulk cement truck transports the cement to the site.

2. Conveying the cement in truck to cement silo by the air pressure of the truck.

3. Conveying the cement in cement silo to the concrete mixer by the screw conveyor.

1. The welding between the bottom legs and pre-embedded parts should be firmed.

2. Installing a lightning rod device on the top of the cement silo.

3. Keeping the pipeline clean when discharging.

4. Checking and cleaning the cement bag regularly.

5. Be sure of the valve switches of the cement silo all in good conditions when changing operator.

6. Checking the pressure gauge regularly to ensure the accuracy of the wind pressure value when discharging.